Valves as Control Elements

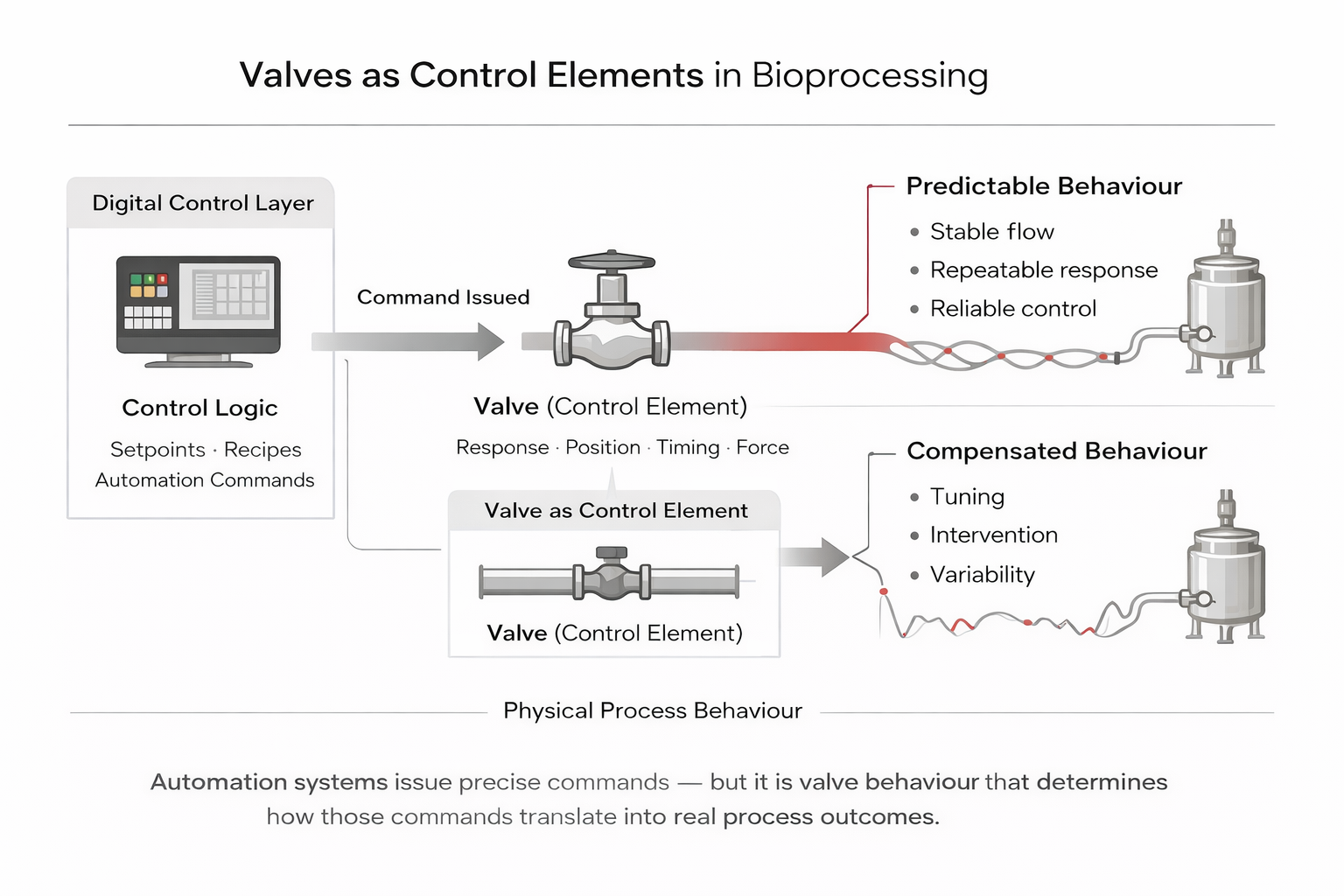

In modern bioprocessing, valves are no longer passive components. They function as control elements — the physical interface between digital control strategies and real-world process behaviour.

Automation systems issue commands based on assumed responses: open to a specific position, close within a defined time, hold under pressure or flow. These assumptions are built into control logic, recipes, and models. Whether they hold true depends not on software sophistication, but on how consistently the valve behaves when those commands are applied.

Because valves sit at critical control points, their response directly affects system stability. When valve behaviour is predictable, control strategies perform as intended. When behaviour is indirect, delayed, or inconsistent, control systems are forced to compensate.

That compensation typically appears as:

Additional tuning and offsets

Broader operating limits

Increased operator intervention

Over time, these adjustments become embedded in workflows and accepted as normal. The system remains functional, but not fully reliable.

In this context, a valve is not just enabling flow — it is shaping how control is executed. The precision, repeatability, and responsiveness of the valve determine whether automation delivers predictability or simply masks variability.

Valves act as control elements where digital automation intent meets real-world process behaviour.