Precision Flow Control for Modern Bioprocessing

Alphinity develop low-shear, single-use valves, pumps, check valves, and bespoke systems that improve fluid handling accuracy, reduce process variability, and protect sensitive biologics across upstream and downstream operations.

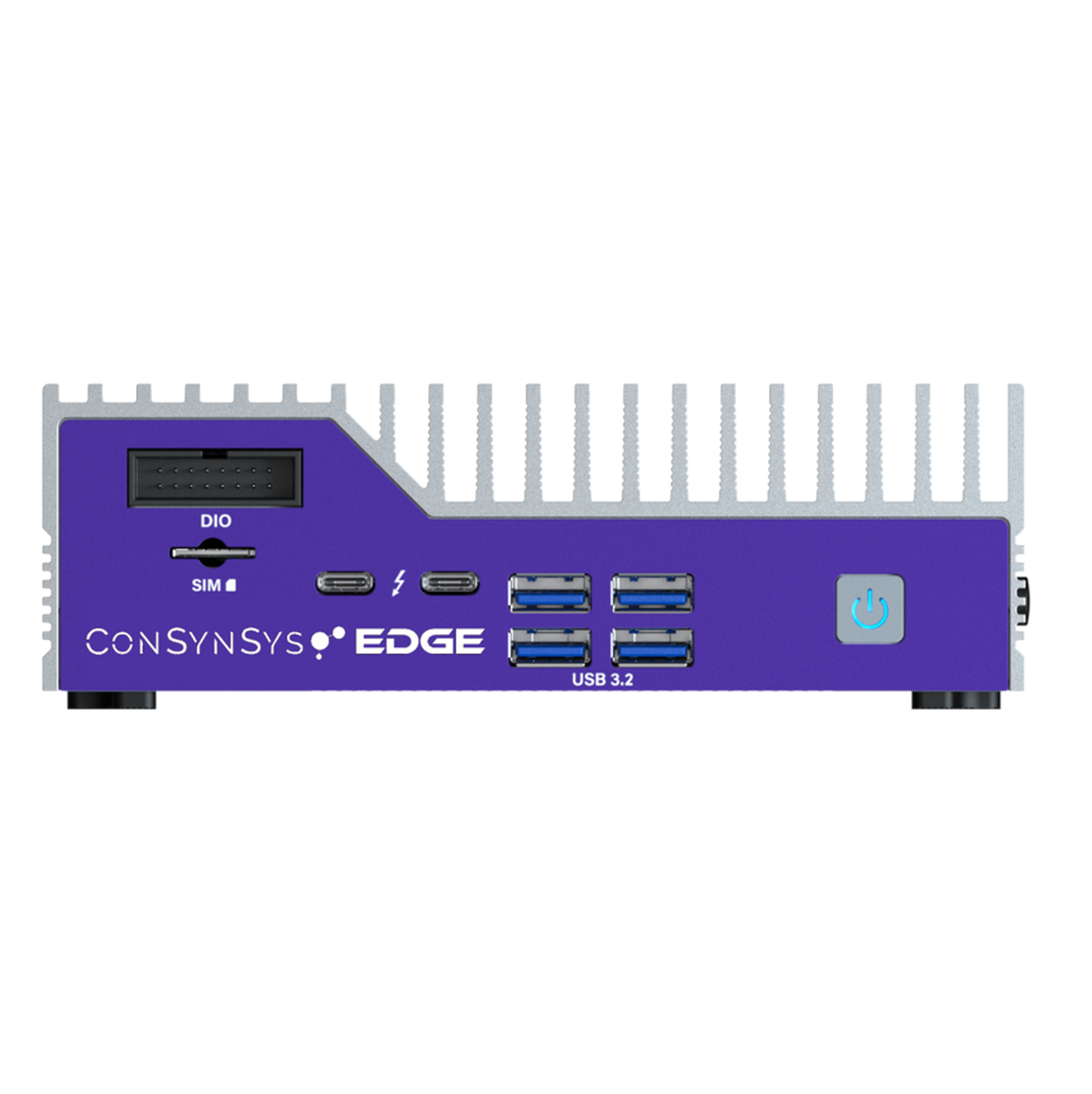

Our systems are configured to support scalable workflows from process development through GMP manufacturing, helping teams improve yield, reduce validation time, and maintain regulatory compliance. Integrated with ConSynSys, a platform that extends beyond automation by enabling real-time monitoring, data-driven control, and predictable process behavior for cell therapies, monoclonal antibodies, and advanced biologics.

Components

Bespoke Systems

Smart Automation

Upcoming Events

Enabling Abundance in Medicine

The Challenges We Address

Modern drug discovery is accelerating faster than ever — driven by AI, platform biology, and new therapeutic modalities.

But for many of these breakthroughs, manufacturing has become the bottleneck.

When Discovery Outpaces Manufacturing

Scientific innovation is no longer the limiting factor.

The challenge is translating novel therapies into real, repeatable manufacturing processes.

Many of today’s therapies are scientifically viable but physically hard to manufacture, because the tools used to produce them were designed for a previous generation of drugs.

As modalities become more fragile, more concentrated, and more complex, legacy bioprocessing technology breaks down.

Where Legacy Technology Falls Short

Across the industry, teams increasingly face:

Fragile and advanced modalities

Therapies such as mRNA, LNPs, viral vectors, and cell & gene therapies that are highly sensitive to mechanical stress.Hidden yield and potency loss

Product damage driven by cavitation, pressure transients, and unstable flow — often misattributed to “shear.”The PD → GMP manufacturability gap

Processes that work at small scale but fail when mechanical conditions change during scale-up.Tools that can’t keep up

Hardware optimised for legacy processes, not the next generation of medicines.

How Alphinity Is Different

We don’t make drugs.

We enable scientists and manufacturers to make drugs that legacy technology cannot support.

Alphinity develops next-generation precision flow control components and engineer-to-order bioprocessing systems designed around flow behavior, pressure stability, and physical process continuity.

Instead of forcing processes to adapt to equipment, we design systems that adapt to the process — from early development through GMP manufacturing.

Our Role in the Industry

Alphinity sits at the critical transition point where therapies move from discovery into real manufacturing.

We provide the tools and systems that allow innovators to:

Protect fragile products

Maintain quality and potency

Preserve physical process conditions during scale-up

Accelerate time from concept to clinic

This is how we help enable the next wave of medicines.

Explore how valve and pump behavior influence bioprocessing performance in our Alphinity Education Hub.