Is it Shear Damage or Pump Damage? The Real Reason Your Biologics Are Losing Potency

We’ve all been there.

You walk into the downstream suite and the pump is hammering away like a jackhammer. It’s so loud you can’t hear yourself think — sometimes you even need hearing protection to have a conversation.

But here’s the thing nobody talks about: that same pump is whisper-quiet when it’s running on water during validation.

So what changed?

The pump didn’t suddenly develop anger issues. Your process did.

And that noise — that violent, rhythmic thumping — is the sound of your protein getting beaten up every time the pump turns.

The Collapsed Tubing Test We’ve All Failed

Raise your hand if you’ve ever run a peristaltic pump a little too fast and watched the inlet tubing collapse flat like a well-squeezed tube of toothpaste.

You stop the run, open the door, and manually massage the tubing back into shape with your fingers because the negative pressure gradient just sucked it completely flat in seconds.

If the pump can do that to thick-walled silicone tubing… what do you think it’s doing to your monoclonal antibody?

The Uncomfortable Truth the Industry Still Won’t Say Out Loud

For twenty years we’ve been told the enemy is “shear stress.”

We’ve spent millions on low-shear tubing, gentle pinch valves, and oversized lines — all to reduce “shear.”

But the data doesn’t lie.

The damage isn’t happening in the tubing.

It’s happening inside the pump.

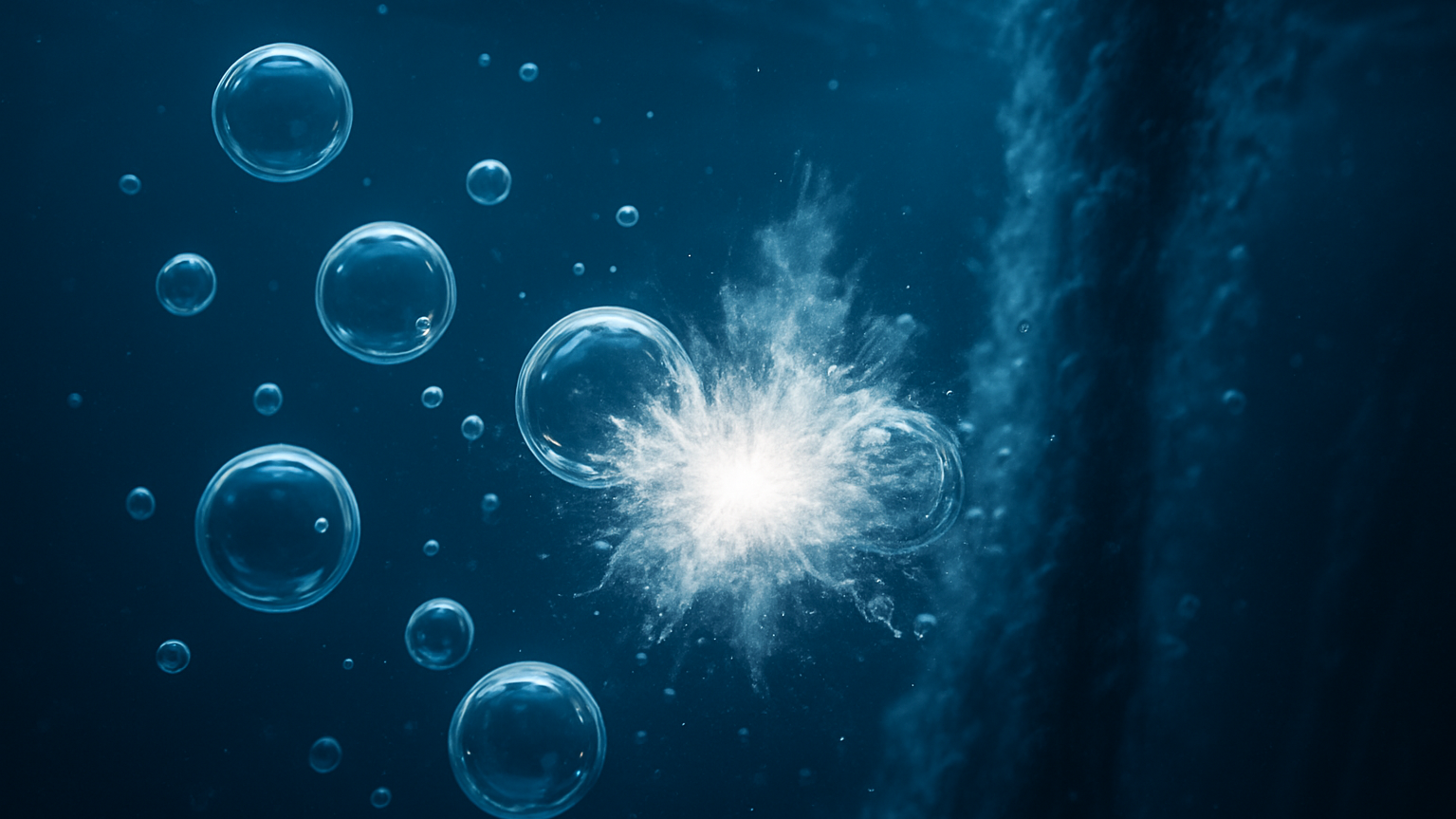

Cavitation. Negative pressure spikes. Hydrodynamic forces from pressure recovery. Bubble collapse generating localised shock waves and temperatures hot enough to denature protein in microseconds.

That’s what’s creating subvisible particles, driving aggregation, and quietly eroding potency — batch after batch.

Pump-induced cavitation impacting biologics

Look Under the Hood of Any “Different” Skid

Take any standard downstream skid on the market today, it doesn’t matter what colour the panels are or what logo is on the front.

Open the door and you’ll find the same thing: a quaternary diaphragm pump (or close equivalent) driving fluid through pinch valves.

Same core technology.

Same pulsation.

Same cavitation risk.

Same protein damage.

The only real difference is the sticker on the box.

The Negative Pressure Gradient Nobody Wants to Talk About

Biologics hate negative pressure.

They really hate it.

When a pump — peristaltic or quaternary — creates a deep negative pressure gradient on the inlet side, it doesn’t just collapse tubing. It stretches proteins, exposes hydrophobic regions, and sets off a cascade of aggregation that no amount of “low-shear” tubing will ever fix.

And every time that pump has to pull against backpressure from a filter or elevation change, the problem gets worse.

The industry has normalised this.

We’ve accepted noisy, aggressive pumps as “just how it is.”

But it doesn’t have to be.

There Is a Better Way

At Alphinity we refused to accept that protein damage was inevitable.

We asked a simple question:

What if the pump never created negative pressure in the first place?

PIXER® is the answer.

A true positive-displacement, single-use diaphragm pump with five diaphragms in radial configuration that delivers perfectly smooth, pulsation-free flow — without cavitation, without negative pressure spikes, and without the violence that has been normalised in every other pump on the market.

No noise.

No collapsed tubing.

No unnecessary protein damage.

Just gentle, consistent, scalable flow that treats your biologic like the multi-million-dollar asset it is.

Stop Accepting Damage as Normal

If you’re seeing unexpected aggregation, mysterious particle formation, or potency drop-off that “no one can explain,” stop looking at your filters or your tubing.

Look at your pump.

Because until you fix the pump, everything downstream is just damage control.

Ready to stop guessing and start protecting your product?

Reach out.

We’d love to show you what truly gentle pumping looks like.

Alphinity.io | Precision Flow Control. Without the Compromise.